Welcome to Buildrock, your trusted partner in high-performance construction solutions. At Buildrock, we understand that every construction project requires materials that not only meet but exceed expectations. That’s why we are proud to introduce our premium Ferro-Silicon Based Microsilica, specifically designed to enhance the strength, durability, and longevity of concrete.

Ferro-silicon based Microsilica is a fine powder created as a byproduct during the production of ferro-silicon, an alloy of iron and silicon. This powder, composed of tiny particles of silicon dioxide (SiO₂), is much finer than cement particles. When added to concrete, it fills in the gaps between cement particles, resulting in a denser and more compact concrete mix.

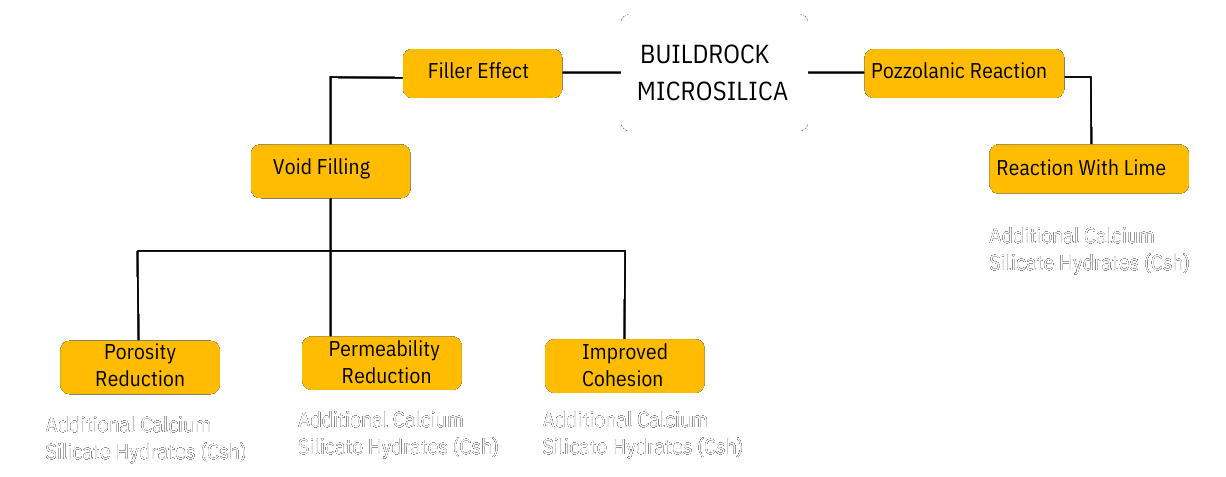

The effectiveness of Ferro-silicon based Microsilica lies in its ultra-fine particles. When added to concrete, these particles fill the spaces between larger cement particles, creating a more tightly packed structure. This process, known as the pozzolanic reaction, occurs when Microsilica reacts with calcium hydroxide produced during cement hydration, resulting in additional calcium silicate hydrate (C-S-H), which is the compound responsible for the strength and durability of concrete.

Our Ferro-silicon based Microsilica is versatile and suitable for a wide range of construction projects:

At Buildrock, we are committed to delivering products that meet the highest standards of quality. Our Ferro-silicon based Microsilica is manufactured under strict conditions to ensure consistency and effectiveness in every batch. Whether you're building a bridge, a high-rise, or an industrial facility, Buildrock Microsilica gives you the strength and durability you need to succeed.

Buildrock Microsilica 153D |

|

Technical Data |

|

Test Result |

|

Buildrock Engineering Pvt. Ltd.

Tower A Paras Twin Towers, Golf Course Rd

Sector 54,

Gurugram, Haryana 122011

+91 9899314000

info@buildrock.in}